On November 24, 2020, SHANDONG SPECIAL EQUIPMENT INSPECTION INSTITUTE GROUP CO., LTD. (SDSEI) signed a special equipment inspection technical service contract with Sudan Khartoum Refinery Co., Ltd. This is the first overseas large-scale petrochemical plant inspection project under general contract management undertaken by SDSEI, which is responsible for providing one-stop trusteeship service and maximum convenience for enterprises.

The overseas inspection task was highly valued by the group leaders. The chairman of SDSEI personally instructed the SDSEI departments to provide key services for the special affairs. Within one month, the procedures of filing, foreign affairs examination, official passport, visa, and other work had been successfully completed. SDSEI has transferred elite cadres from various business departments to establish the Sudan Project Department and established a temporary Party branch quickly to ensure that the Party branch can play the command role in time at the inspection site. The personnel of the Project Department worked overtime to prepare the Chinese and English inspection technical scheme and COVID-19 prevention and control scheme, arranged the relevant personnel of safety, quality, technology, materials, equipment, and logistics to form the HSE Support Group, assigned the personnel of the project department in groups, assigned the responsibility to each person, made reasonable arrangements for the inspection equipment and logistics in advance, and made a good man-machine relocation scheme.

(Contributor: Lyu Xianwei)

(I) Departure

With the strong support of the leaders of the group and SDSEI, the Project Department has made meticulous preparations for the inspection in Sudan for nearly a month. The preparation includes making inspection plan and site operation instruction document; preparing Chinese and English inspection report and original record format, and engraving Chinese and English inspection seals; preparing inspection instruments and equipment, and calibrating them; purchasing inspection consumables and necessary on-site living materials, and handling customs clearance procedures; organizing the personnel to be familiar with the parameters and operation status of the equipment, so as to have a clear idea of the equipment status; inoculating the vaccines for entering into Africa and COVID-19 pandemic according to the state's regulations. Two days before departure, all members of the Project Department carefully checked and packed the work materials, living materials, COVID-19 prevention materials, and other necessities in advance. At 8:00 a.m. on December 28, the members of the Project Department set off with the farewell of the leaders and colleagues of SDSEI.

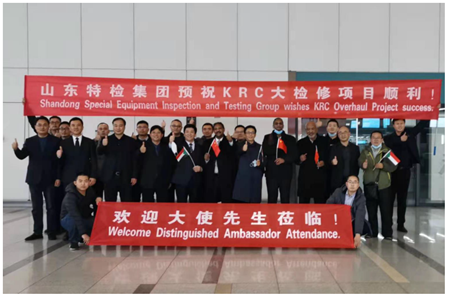

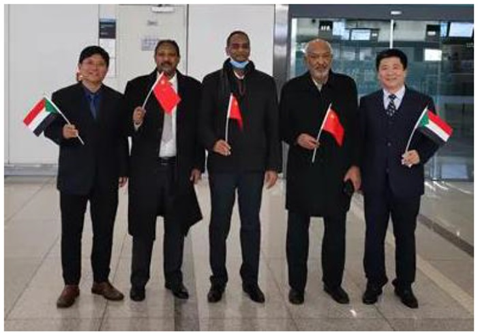

On December 29, 2020, Zhang Minsheng, chairman of SDSEI, Zhang Feng, general manager of SDSEI, and Dr. Gafar Karar Ahmed, Ambassador of the Republic of Sudan to China, saw off the Project Department members at Hangzhou Xiaoshan International Airport. Bearing the responsibility of public welfare state-owned enterprises and the earnest instructions of leaders, the members of the Project Department set foot on the journey with high morale.

(II) COVID-19 Prevention and Control

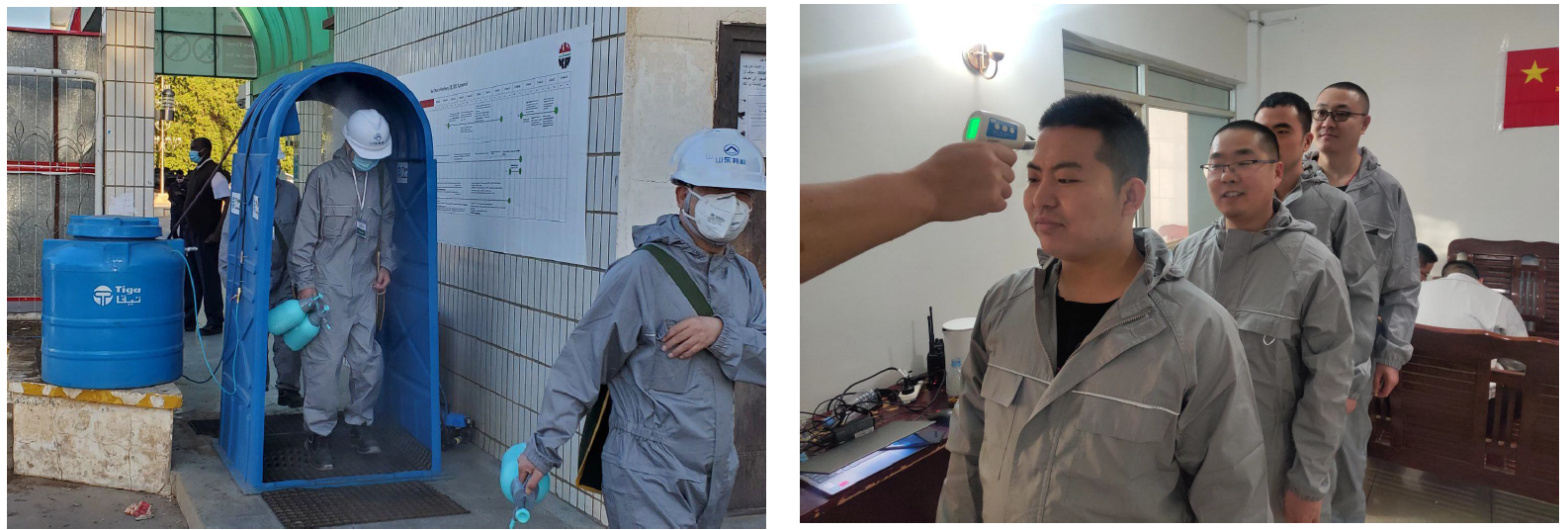

In the special period of the COVID-19 pandemic still raging in foreign countries, its prevention and control is the most important work. Two days before departure, all members of the Project Department were vaccinated with the COVID-19 vaccine after the coordination by the leaders. During the flight, all members strictly implemented the scheduled pandemic prevention plan, wore protective clothing and masks, and minimized the number of meals and drinks on the way. After a 28-hour long-distance flight, members of the Project Department arrived at Khartoum International Airport at 1:30 a.m. Beijing time and 7:30 a.m. Khartoum local time on December 31, 2020.

After arriving at the plant, the Project Department formulated strict pandemic prevention measures as follows. 1. When going out, masks, eye masks, or glasses must be worn strictly; 2. In line with the requirements of pandemic prevention in the factory, the social distance should be strictly maintained when contacting people in the factory, and the transmission route should be cut off; 3. Do not touch eyes, nose, mouth, and other parts after going out; 4. After returning to the dormitory, the mask should be turned out and discarded, the outer coat and safety helmet should be placed separately and sprayed with disinfectant, and handwashing and disinfection should be carried out immediately; 5. Try not to eat or drink water when going out, and clean and disinfect hands before meals; 6. The body temperature shall be measured and recorded twice a day at noon and evening. The dormitory shall be sprayed with disinfectant every day.

(III) Work

At the beginning of 2021, 33 inspectors from SDSEI have gone to Khartoum Refinery (KRC), Sudan, Africa, to be responsible for the on-site inspection work.

After arriving at the plant, the Project Department quickly entered the working state and divided the inspectors into five groups, respectively responsible for five devices. Each group is responsible for its device while flexibly mobilizing to help the test of other groups. After two days, they have completed the processing of admission documents, familiar with the rules and regulations of the factory and the processing process of various operation tickets. Each group has found out the position of the pressure vessel to be tested, and the pipeline diagram of the pressure pipeline is also being drawn. The Project Department held a regular meeting after work every day to report problems and summarize experiences. Each group will make a written report on the daily work content and the next day's work plan. Although it was New Year's Day holiday in China, all the inspection personnel are working hard and fighting on the front line. As of January 3, 2021, the Project Department has been in the factory for five days, and has completed the inspection work of 26 pressure vessels and 3 pressure pipes.

(IV) Life

According to the working hours of Khartoum Refinery, the personnel of the Project Department got up at 5:15 a.m., ate at 6:00 a.m., and entered the plant on time before 7:00 a.m. to carry out the inspection work.

After 11:00 a.m., they left the inspection site and went to the temporary canteen for lunch. At 1:00 p.m., they entered the factory to start the inspection work in the afternoon. After dinner at 6:00 p.m., they sorted out the inspection records of the day. At 7:30 p.m., they held a daily work meeting to summarize the problems found in the inspection of the day and arrange the work plan for the next day.

Because the temporary dormitory is uninhabited for a long time, there are many cockroaches in the room. According to the pandemic prevention and control requirements of the Project Department, special personnel is arranged to do the protection and disinfection work every day.

(Contributor: Liu Wei)

Introduction to the Sudan Khartoum Refinery Inspection Project

Khartoum Refinery is located 70 kilometers north of Khartoum, the capital of Sudan, and adjacent to the Nile River in the West. The revamped refinery was built with the assistance of China National Petroleum Corporation (CNPC) and other Chinese-funded enterprises according to Chinese standards and was completed and put into operation in 2000. Its inspection and testing standards and specifications are in accordance with China's special equipment law, regulations, and safety technical specifications. Covering an area of 860,000 square meters, the plant is composed of more than 50 production units including the catalytic unit, the delayed coking unit, and the continuous reforming unit, with an annual crude oil processing capacity of 5 million tons. The oil refining industry is an important economic pillar of Sudan and the main source of foreign exchange. The products of Khartoum Refinery are directly related to the national economy and people's livelihood. Products such as polypropylene, plastic woven bags, and rainproof cloth, would directly affect the national economy. Gasoline, aviation kerosene, diesel oil, and liquefied gas of Sudan are also mainly produced by Khartoum Refinery. If the refinery stops production for a long-term overhaul, the life of the people in Khartoum will be affected due to an insufficient supply of liquefied gas. Therefore, the duration of the overhaul is strictly estimated and must be guaranteed. Because some devices have been in operation for more than 20 years, the Government of Sudan has paid close attention to them and asked to select the most first-class team in China to participate in the maintenance and inspection work. Originally planned to shut down for production and maintenance in March, the project was delayed due to the COVID-19 to the end of December. The Government of Sudan requested that the overhaul work should not be delayed any longer and that it must be started in late December and completed on schedule. The Ambassador of Sudan to China personally went to Hangzhou Xiaoshan International Airport to saw off the inspectors, which showed how important this task is to Sudan.

This overseas inspection project was of great significance. SDSEI took this project as an opportunity to make itself a high-quality brand of special equipment inspection and vigorously explore the African market. In the future, it will focus on major oil refineries built with Chinese assistance in Niger, Chad, Algeria, and other countries, and gradually expand the market share of overseas business in Africa. The inspection period is more than 50 days. During this period, the COVID-19 situation in foreign countries is still very serious. All members of the Project Department stayed away from the motherland, hometown, and loved ones, and spent the New Year's Day and the Spring Festival in Africa thousands of miles away, which reflected the SDSEI people's courage to fight and dedication.

Appendix: Satellite image of Khartoum Refinery

(Contributor: Cui Lele)